Industrial & Manufacturing Solutions

Surface Finishing and Gluing Production Machinery

In order to offer the customer a complete solution, we have the most extensive test center available.

Located in the Netherlands, near Amsterdam (Schiphol Airport) so very easy to reach by travel.

Our machinery uses high-end materials, ensuring long lasting quality and minimizing downtime.

If you want to test your products on our machinery, you're always welcome to contact us to visit our Test Center.

Who we are

Precision surface finishing & gluing machinery

At Soest Machinery, we specialize in innovative, high-quality machinery for the wood and surface treatment industry. With years of expertise and advanced technology, we deliver tailored solutions for gluing, pressing, coating, aging, brushing, sanding, drying, and more.

Our core values – quality, precision, and collaboration – guide us in creating efficient, reliable machines. We work closely with you to design and deliver systems that elevate your production and bring your vision to life.

With over 40 years of experience and over 500 active clients, we have established a strong and secure position worldwide. We can also communicate in English, Dutch, French, Spanish and German.

Why Choose us

Industrial Production Solutions

At Soest Machinery, we deliver more than machines – we provide expertise, reliability, and tailored solutions that drive your success. With a commitment to innovation and precision, we create efficient, durable systems designed to meet your unique needs. Partner with us for exceptional quality, personalized service, and machines that elevate your production to the next level.

Soest has over 40 years of experience in this industry.

Soest Machinery has realised projects in all continents.

During the years, Soest Machinery has built up over 500 active clients.

Soest Machinery can communicate in English, Dutch, French, Spanish and German.

Advanced product testing possible in our Test Center, located in The Netherlands.

Soest machinery is active in different industries like wood, concrete, felt, cardboard, glass, foam, etc.

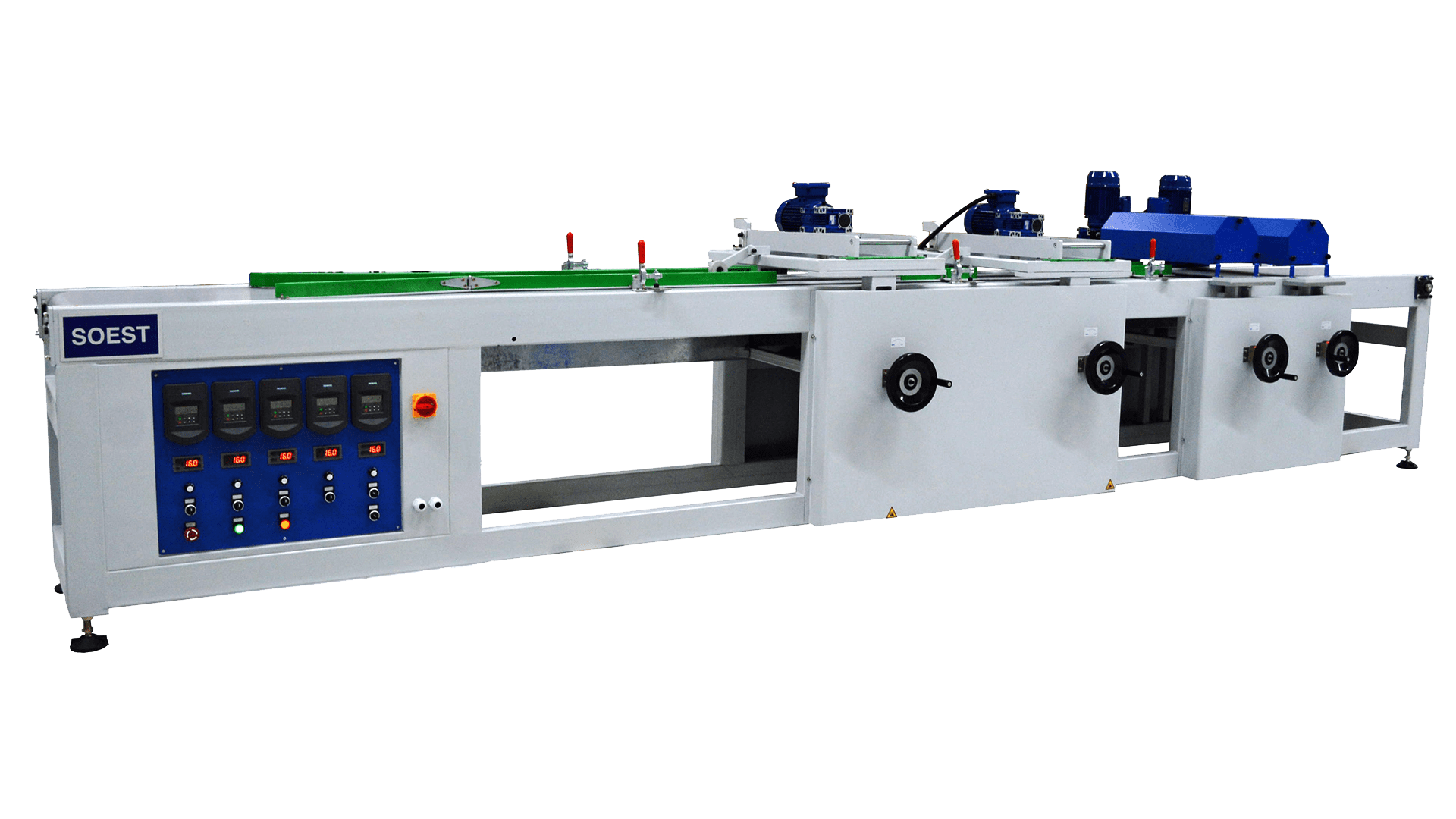

Our Machinery

It's all about Finishing and Application

In order to offer the customer a complete solution, we have the most extensive test center available.

Roller coating - Spraying - Curtain coating

Soest specializes in the application of lye, stain, oil, paint, and lacquer, offering tailored techniques for applying, polishing, and drying coatings. Machines are available in various widths and designs, with rollers customizable with coverings like NBR, EPDM, and sponge to suit different coatings.

Hotmelt roller coater - Cold glue roller coater

Our advanced gluing systems are designed for precise application of adhesives on materials like wood, veneer, and panels. With support for various glue types, including PVAc, PU and different kinds of Hotmelt. Our solutions ensure strong, reliable bonds tailored to your production needs.

Roller presses - Flat presses

Pressing solutions from Soest Machinery deliver consistent and durable results for glued materials. From roller presses to flat press plates, our machines are built for efficiency and reliability, handling everything from engineered flooring to sheet materials with precision.

Brushing - Cross cutting / Edge scraping

Structuring brings out the natural wood grain using specialized brushes, such as soft bronze, Tynex, or heavy metal. This technique creates unique textures, including “reclaimed timber” effects, for a distinctive and rustic appearance.

Brush Sanding - Belt Sanding

Before applying a coating, wood often needs to be sanded to achieve a smooth and even surface. This process ensures better coating adhesion and delivers a flawless, professional finish.

UV (Ultra-Violet) - LED (Light-Emitting Diode) - Air and/or IR (Infra-Red) - Drying racks

After applying coatings like lye, stain, oil, or UV lacquer, drying is essential before packaging. Various techniques are available, including air drying tunnels, infrared radiators, UV lamps, LED modules, and drying racks, tailored to the specific coating.

Infeed system - Conveyors - Turning system - Transfer system - Drying racks

This product group offers versatile solutions applicable across other categories, including transporting and handling wooden floorboards, sheet materials, and profiles. Custom solutions are available for infeed, turning, outfeed, and stacking processes.

Polishing machine - Brush cleaner - Pad cleaner

Polishing and buffing machines are designed for polishing lye, stain, oil, and lacquer on flat workpieces like wooden floors. Built for industrial use, these robust machines feature a welded framework that ensures vibration-free operation and long-term reliability.

Advanced Gluing Solutions

Gluing is at the heart of what we do at Soest Machinery. Our high-tech gluing systems are designed to deliver strong, seamless bonds for parquet, panels, and more. With precision engineering and customizable solutions, we ensure durability and efficiency in every project. Discover how our gluing expertise can elevate your production process.

Advanced Coating Solutions

In addition to gluing, coating plays a vital role in our solutions at Soest Machinery. Our advanced coating systems are developed to apply protective and decorative finishes to parquet, panels, and more. With precision control and tailored configurations, we help you achieve optimal durability, visual appeal, and production efficiency. Discover how our coating expertise complements your finishing process and enhances the final result.

Soest Machinery Test Center

How can you most efficiently finish wooden products with stain, lye, oil, lacquer or paint? How can you best age/distress, brush, sand or dry a wooden floor or other product? How can you glue and press wooden products, sandwich panels, honeycomb, or different materials?

Frequently asked questions to which Soest gives you answers in the Test Center.

In order to offer the customer the best solution, it is possible to test your materials in our Test Center. This ensures satisfactory results. We can also train your staff/employees here to operate the machines in the correct way.

How we work

From Concept to Completion: A Seamless Process

At Soest Machinery, we combine innovation, precision, and expertise to deliver custom-built machines that enhance your production process. From initial consultation to final installation, we work closely with you to ensure every solution meets your unique requirements. With state-of-the-art demonstrations in our test center and comprehensive training and support, we guarantee seamless integration and long-term success. Partner with us to take your production efficiency to the next level.

Consultation & Design

We discuss your needs and production requirements to find the best solution. Based on this, we prepare a custom-made quote including descriptions of the machines, specifications, additional options, prices, and delivery terms.

Demonstration at Our Test Center

Before production begins, we invite you to our test center to see a demonstration of (similar) machines in action. This ensures you fully understand its capabilities and suitability for your application. It is also possible to bring and test your own products here.

Our history and team

Discover who we are, our rich history dating back to 1983, and how we’ve grown into a trusted provider of custom machinery solutions. Learn about our commitment to quality, innovation, and building lasting partnerships with our clients.

Training & Support

After installation, we provide thorough training for your team. With ongoing support, we ensure your operations run smoothly and efficiently.

What’s your edge when competing on quality? Precision in gluing and coating means cleaner results and fewer defects. Consistency is your competitive advantage.

#qualitycontrol #productionvalue #gluingtech #coatingtech #manufacturing #industrial #engineering

...

What’s the advantage of inline gluing and pressing? Combine PUR gluing with a roller press for seamless flow, no delays, no shifting, no manual steps.

✔ No clamps or wait time

✔ Ready for cutting or packing instantly

#hotmelt #rollerpress #automation #manufacturing

...

Uneven results or waste issues? Roll height, alignment, product type or temperature could be the cause. We recommend you to reach out to us if any issues occur. Our team is always available for technical support.

#industrial #machinery #support #production #quality

...

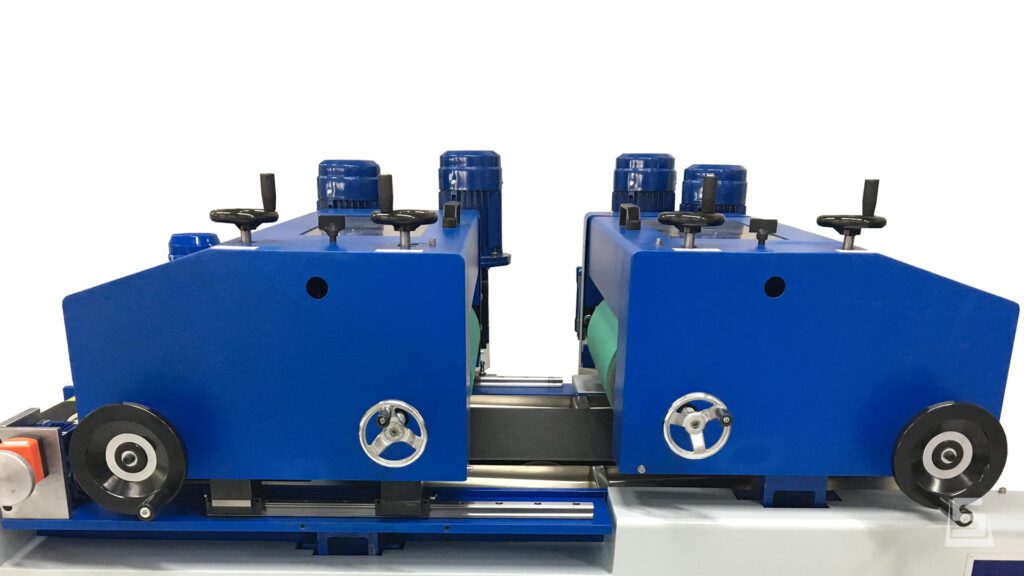

Why invest in a Twin Roller Coater? Apply two colors or coats without cleaning in between. Ideal for wet-in-wet coating or switching products fast.

✔ Dual application in one pass

✔ Minimal downtime

#rollercoating #twinsystem #woodfinishing #machinery #mdfcoating

...

A complete oiling line built for performance. From coating to polishing, this setup delivers consistent results on structured wood.

✔ Modular setup

✔ Scalable speed

✔ Test it in the Netherlands

#woodcoating #industrialoiling #flooringproduction #soestmachinery

...

How can PUR hotmelt improve flooring production? PUR hotmelt bonds all kind of materials fast, no clamps, no waiting. Built for high-output flooring lines.

✔ Strong, lasting adhesion

✔ No drying time

✔ Inline cutting & packing ready

#hotmeltglue #lamination

...

The benefits of curtain coating. Curtain coating offers smooth and even coverage, with higher product output than roller coating. Ideal for flat or uneven surfaces.

✔ Uniform thickness

✔ Fast application

#coating #machinery #curtaincoating #application #industrial #finishing

...

Our approach to quality control. Quality starts long before the final product. Every machine is tested for consistency, compatibility and durability, because downtime is not an option in production.

✔ Built to perform

✔ Tested to last

#machinery #production #engineering

...

How can sanding reduce coating defects? It removes dust, fibers, and micro flaws that weaken coating adhesion.

✔ Better surface bonding

✔ Fewer finish issues

✔ Cleaner, smoother results

#sanding #surfaceprep #woodcoating #industrialmachinery #qualityfinish

...

Trusted by 2000+ customers in the finishing and application industry