Imagine a process where your materials are glued, pressed, and immediately ready for cutting or packaging — with no drying or curing time in between. That’s the power of a continuous gluing and pressing line using PUR hotmelt technology.

How it works:

- Step 1: Hotmelt roller coater applies a consistent layer of adhesive

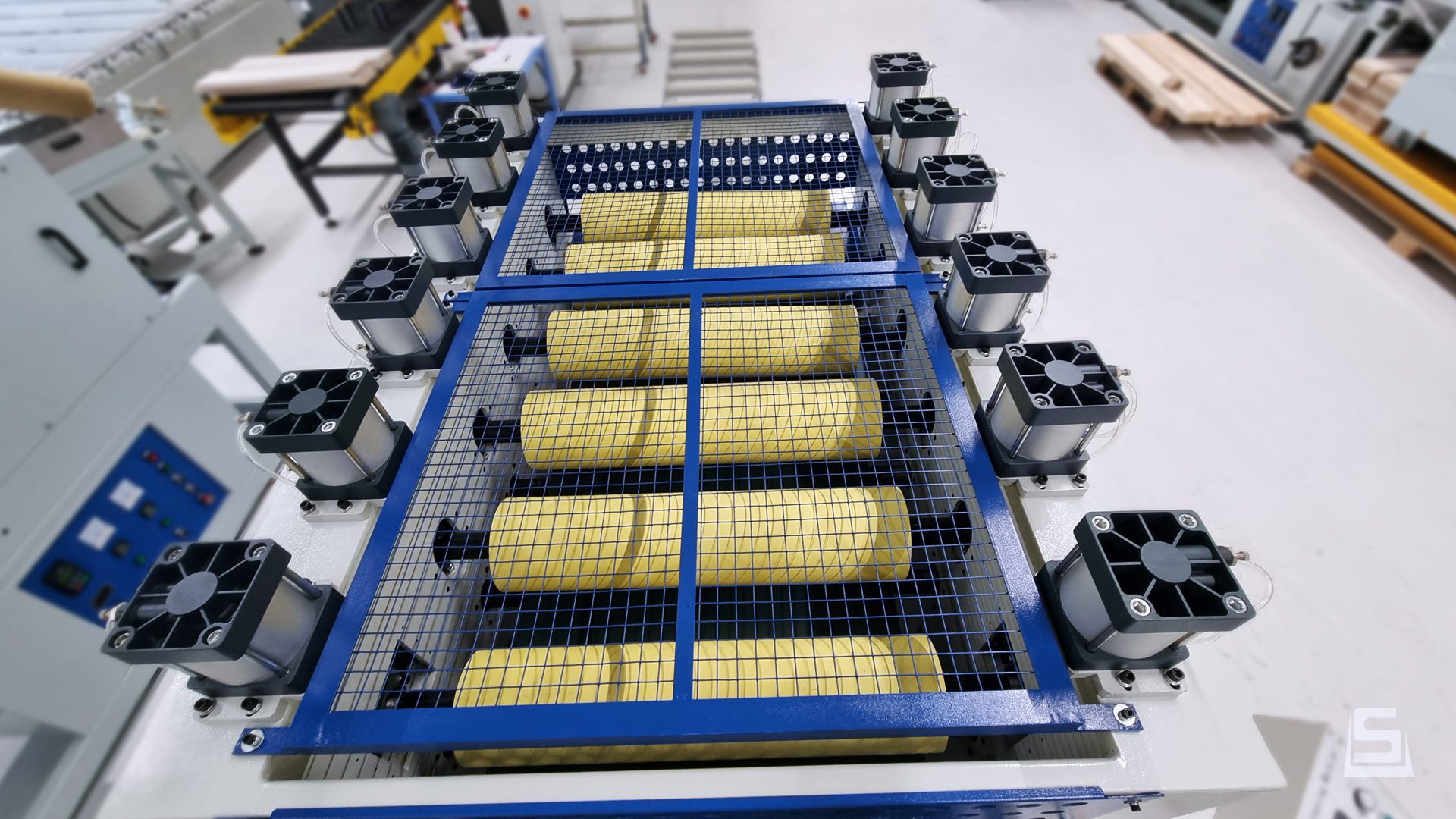

- Step 2: Calander roller press bonds the material under uniform pressure

- Step 3: The product exits the line ready for cutting, wrapping, or assembly

Applications:

- Slats on felt (acoustic panels)

- Foam lamination

- Flooring layers

- Decorative foils on wood-based panels

Why choose this setup?

- Continuous flow = no delays

- Stable, clean, and fast bonding

- Reduced handling and fewer quality issues

Want to test your materials?

We invite you to our Test Center to simulate your process and get immediate results.