Manufacturers of acoustic wall panels often face the same issue: slats that come loose after cutting or trimming. Traditional stapling or cold glue techniques can’t always ensure full bonding across the entire surface. That’s where PUR hotmelt adhesive steps in — offering both speed and long-term stability.

Why PUR hotmelt makes the difference:

- Full-surface bonding: Even after trimming, every slat remains fully adhered to the base layer (e.g. felt or MDF).

- No drying time: The adhesive bonds instantly, making the process much faster than cold glue systems.

- Cleaner look: No visible staples or mechanical fasteners.

- Flexible materials: Works with felt, foam, wood, and more.

Real-world application:

Many of our clients have successfully switched from mechanical fixing to hotmelt gluing for slatted acoustic panels. The result? Reduced waste, fewer returns, and higher customer satisfaction.

Want to see it in action?

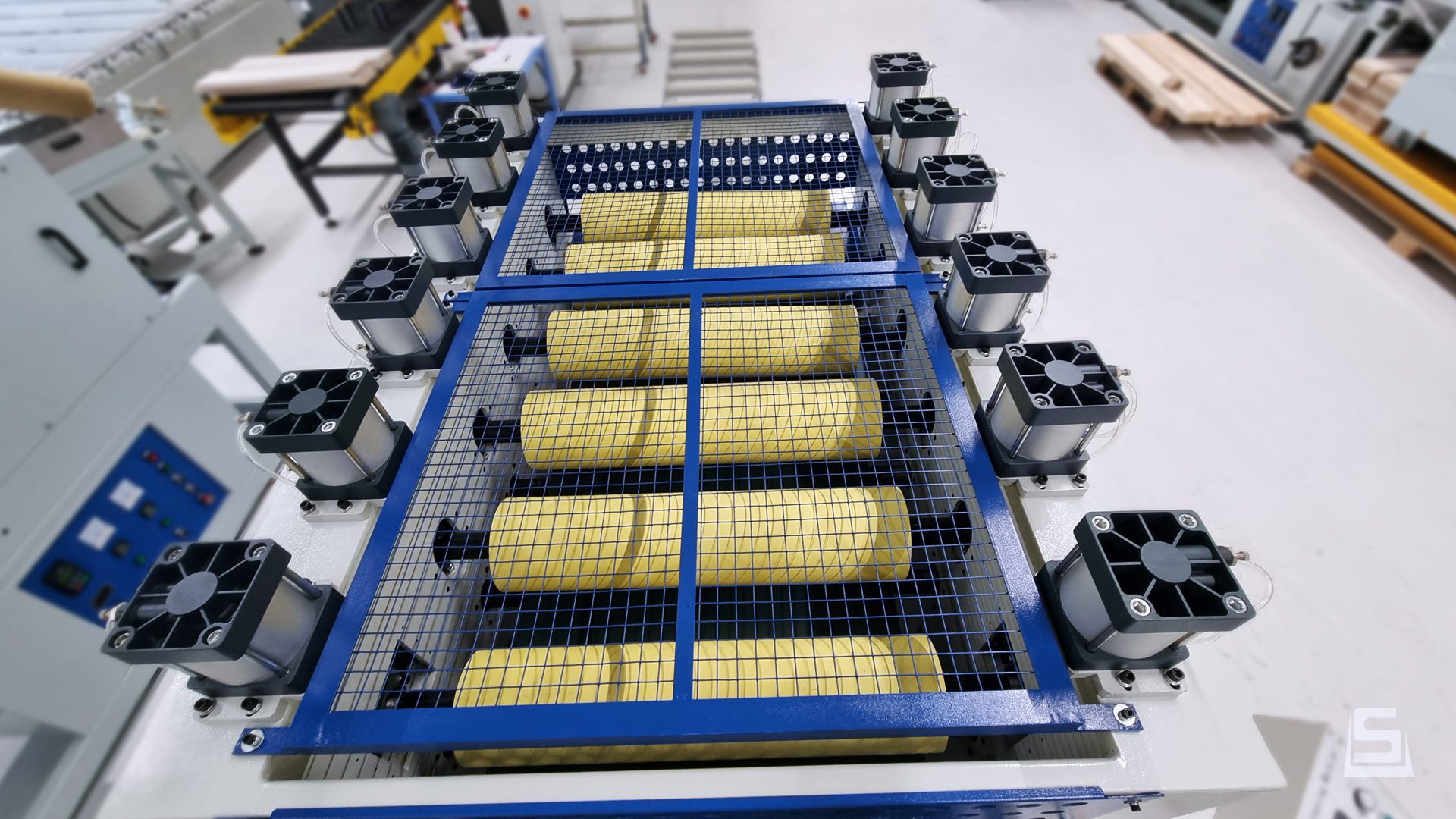

Visit our [Test Center] or request our demo video showing how slats are bonded and pressed in a continuous flow.